A massive factory overhaul sets the stage for over 40 new electric models by 2027

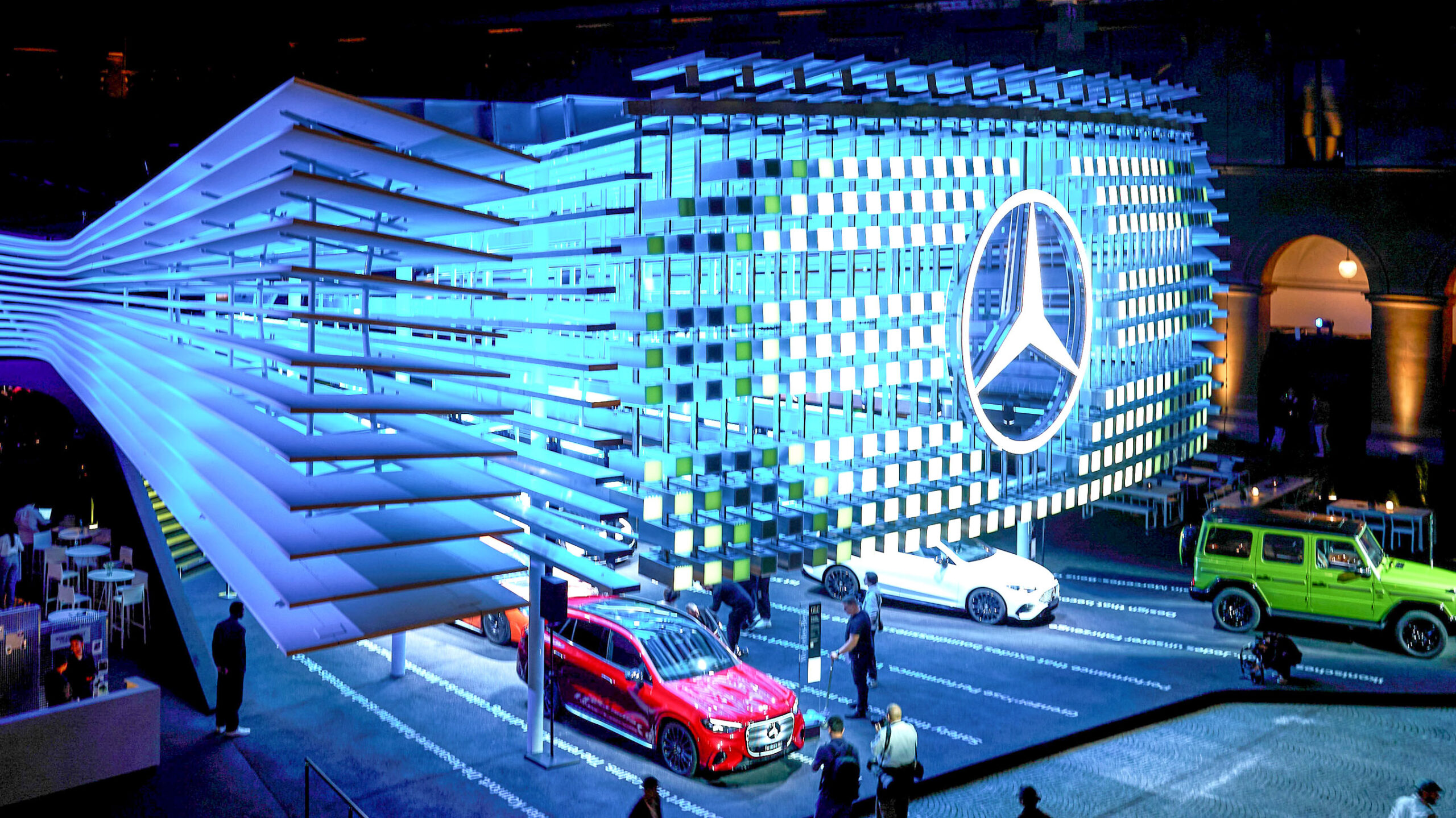

The arrival of the new all-electric Mercedes-Benz GLC with EQ Technology marks more than just a significant model launch. It also signals the start of what Mercedes describes as the largest product offensive in its history.

Read: Star-Stricken Mercedes GLC EV Has A Grille Big Enough To Swallow A BMW iX3

Over the next three years, the company plans to launch more than 40 new models while working to significantly cut production costs. At the same time, it is making the controversial shift away from a pure luxury focus in order to pursue higher-volume, more affordable vehicles aimed at strengthening its financial position.

To prepare itself for a slew of new models, Mercedes has invested more than €2 billion ($2.3 billion) in its European assembly plants. Once the production ramp-up of the new electric CLA is completed at its Rastatt site in Germany, the brand will start building the GLC EQ in Bremen as well as the all-electric C-Class EQ in Kecskemét.

Expanding the Lineup

At the same time, the carmaker’s Sindelfingen plant will begin producing new electric models from Mercedes-AMG, including the production version of the recently unveiled Concept AMG GT XX.

While speaking at the launch of the new electric GLC, Mercedes-Benz chief executive Ola Källenius noted that “with the new electric GLC, the biggest product launch in our company’s history continues to gain momentum.”

Among the lesser-publicized additions is the upcoming VLE, an all-electric luxury MPV developed on the company’s new Van Electric Architecture. Designed to carry up to eight passengers, it highlights Mercedes’ intent to cover a broad range of segments. The lineup also expands with an electric “baby” G-Class SUV, a refreshed S-Class, next-generation versions of the GLA and GLB, and more.

Digitialization and AI

As Mercedes ramps up the production of several new models in Europe, it’ll integrate its MO360 and MO360 Data Platform production ecosystems into the plants, allowing for ‘digital twins’ of the sites to be made, where future improvements can be tested and verified before being implemented into the plants.

More: Mercedes Drops The “L-Word” And Is Ready To Flood The Streets With Mainstream Cars

Mercedes-Benz has also said that it will decrease production costs by 10 percent between 2024 and 2027. In addition to using digitalization to help achieve this, Mercedes will use artificial intelligence, increase the use of renewable energy, and push for greater production and logistics efficiency.

Google News

MSN Start

Brad Anderson’s lifelong affair and fascination with cars started young. Before even graduating high school,… Read full bio