Finnish technology company Donut Lab has unveiled DonutOS. The software platform aims to revolutionize nothing less than “the conception, development, and realization of electric vehicles.”

Donut Lab is now a subsidiary of electric motorcycle manufacturer Verge Motorcycles and is best known for its ‘Donut Motor’, a hub motor integrated into the wheel rim. This design, featured in the Verge TS Pro, creates the illusion of a hollow rear tyre. In January, Donut Lab unveiled a 630-kW version of this motor for electric cars and other vehicles.

The company’s latest innovation, the DonutOS software platform, extends beyond electric two-wheelers. DonutOS integrates “virtual modelling with real vehicle behaviour,” creating what the company terms Digital Twin 2.0. This platform is designed to streamline the entire vehicle development process—from concept to production—within a single software environment. “Automotive development has long been constrained by fragmented tools and slow physical prototyping. As electric vehicles have evolved into complex, software-driven systems, these challenges have only grown,” the company notes in its announcement.

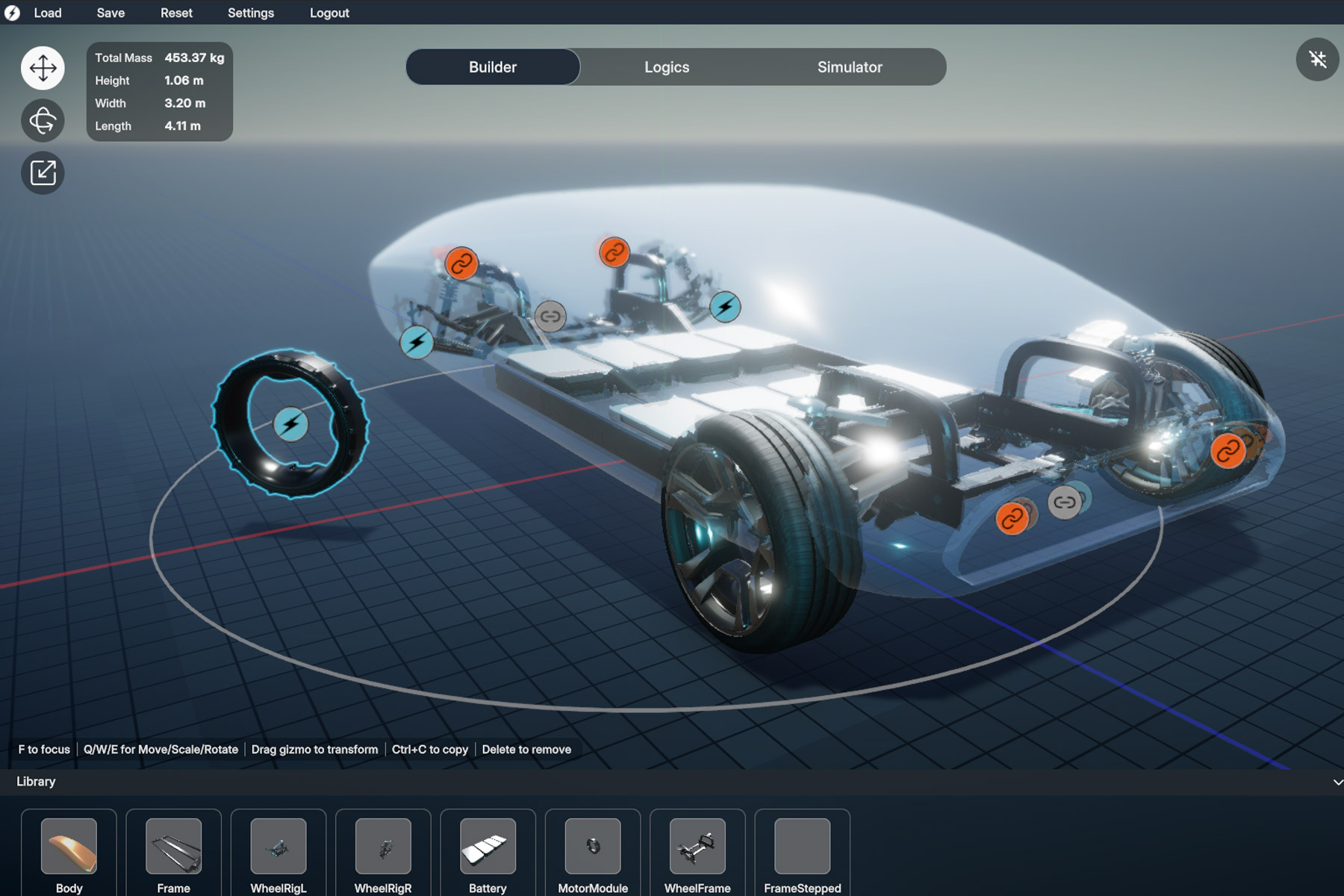

DonutOS consolidates the entire workflow into one cohesive environment, “enabling teams to design, simulate, validate, and refine vehicle behaviour even before hardware exists.” Traditional development follows rigid phases—physical prototyping, lab testing, track testing, and software integration. “DonutOS replaces this with a unified platform where mechanical, electrical, behavioural, sensory, and UI systems are developed collaboratively,” explains Donut Lab.

This approach is expected to shorten development cycles from years to “months or even weeks.” By simplifying processes and reducing personnel requirements, “startups without large engineering teams can now design vehicles with the complexity of major OEMs.” For established manufacturers, the platform significantly cuts prototype development costs. Additionally, “software-driven vehicle strategies become feasible, as updates and new features for digital and physical fleets can be designed, tested, and deployed with absolute consistency,” the company highlights as a key benefit.

The term ‘Digital Twin 2.0’ reflects Donut Lab’s claim that earlier digital twins only modelled isolated vehicle components, not the entire system behaviour. With Digital Twin 2.0, DonutOS creates an “interactive, virtual vehicle” where “all systems, sensors, controls, and data flows are fully mapped.” Engineers can test a complete electric vehicle and its responses to real-world conditions, environmental factors, and sensor inputs before any physical prototype is built.

“DonutOS empowers manufacturers to develop the entire vehicle—hardware, software, and behaviour—as a single digital entity. Our goal is to enable smaller mobility companies to innovate faster, even without the resources of large OEMs,” says Marko Lehtimäki, CEO of Donut Lab. “Innovation shouldn’t be limited by size. With DonutOS, we’re levelling the playing field and making advanced development tools accessible to all.”

There’s a catch: DonutOS is not yet publicly available, with a release date to be announced “at a later time.” To begin, Donut Lab has launched a “Global Innovators Program” to provide early-stage electric vehicle companies with early access to technologies like DonutOS, along with tailored technical support and preferential pricing for low-volume production.

Source: Info via email

Your email address will not be published.

electrive has been following the development of electric mobility with journalistic passion and expertise since 2013. As the industry’s leading trade media, we offer comprehensive coverage of the highest quality — as a central platform for the rapid development of this technology. With news, background information, driving reports, interviews, videos and advertising messages.

© 2025 electrive.com