© 2025 Power Automedia.

All rights reserved.

When we last visited the ongoing build of our T-Rex project car, a restomod 1974 TVR 2500M powered by a 5.0L Ford Coyote engine, Wilwood disc brakes were installed fore and aft, the chassis plumbed and enlarged front wheel wells fabricated. Completing the drivetrain was next on the agenda.

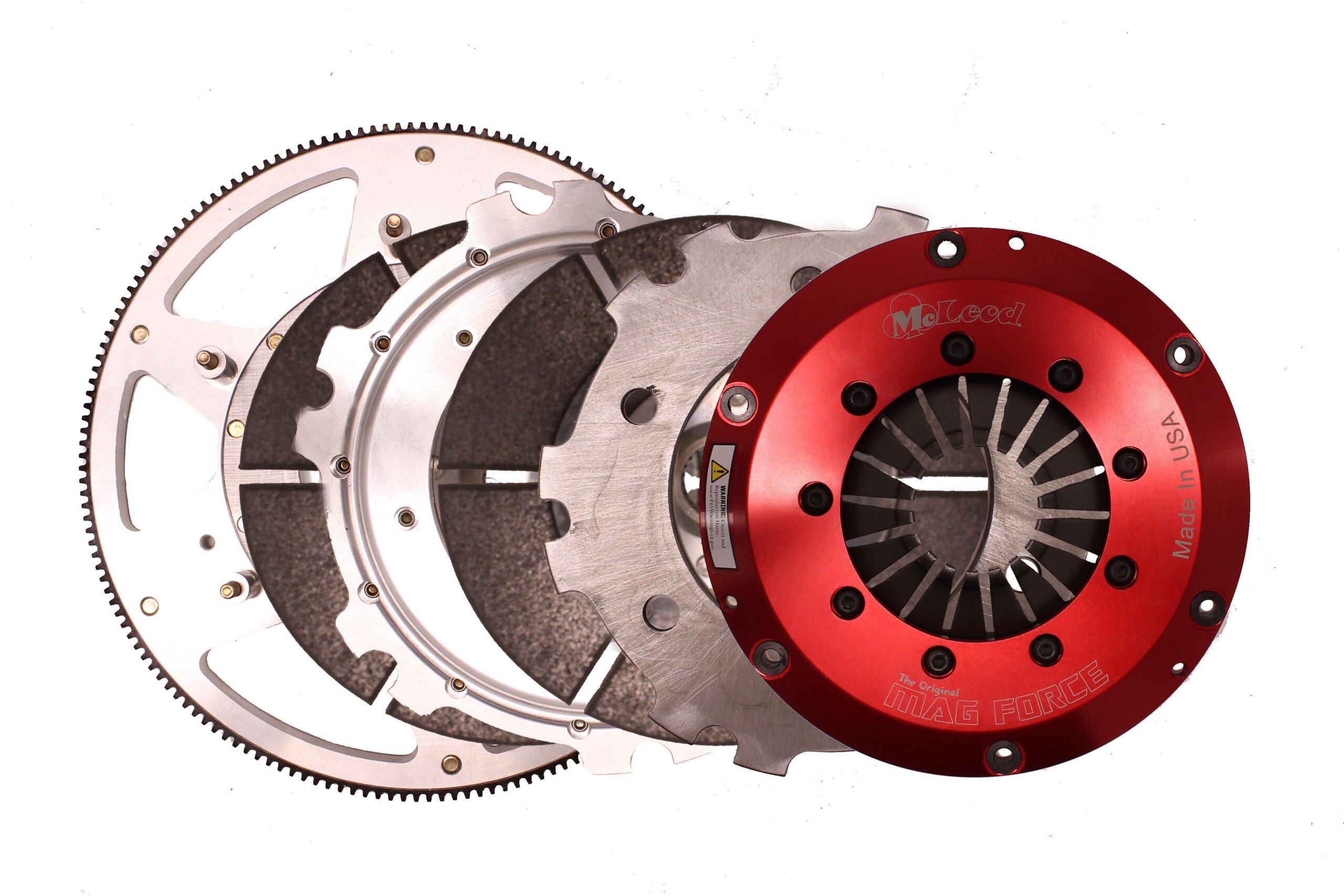

For the clutch, a McLeod “Mag Force” two-disc setup was deemed ideal for the application. It’s a street/strip clutch rated at 900 lb-ft of torque, while the single disc comes in at 500 lb-ft — which the T-Rex project car’s engine will hopefully exceed when some nitrous is applied. The hat is billet aluminum and anodized red, while the discs are 8-inches in diameter. Both metallic and organic discs are available, but given the desire to do some serious autocrossing with T-Rex, the decision was made to go metallic.

Given T-Rex’s performance parameters a McLeod “Mag Force” clutch was selected. It’s a dual-disc unit with 8-inch diameter discs. This unit has metallic discs; organic ones are available. It’s rated at 900 lb-ft of torque, which is far higher than the stock Coyote’s potential.

To ensure a secure installation, ARP clutch and flywheel bolts were employed.

When T-Rex’s build was originally configured in 2018, the plan included a McLeod Musclecar five-speed transmission. Given the car’s light weight, estimated to be around 2,100 pounds, it made good sense to use a five-speed in lieu of a six-speed, as the extra gear step wasn’t needed to move the mass (as would be the case with a heavier vehicle).

Here’s the complete clutch/flywheel assembly installed in T-Rex. The pedal pressure is quite comfortable.

Build plans can certainly change in mid-stream, and such was the case with the transmission. TREMEC introduced its TKX five-speed a few years ago and it’s very robust. In fact, it’s rated at 600 lb-ft of torque as opposed to the former’s 500.

And as a bonus, the TKX employs the same synchro technology as TREMEC’s Magnum.

This facilitates improved shifting at high RPM — a plus for the high-winding Coyote. TREMEC’s model TCET17805 was selected, which has gear ratios of 2.87 (1st), 1.89 (2nd), 1.28 (3rd), 1.00 (4th) and 0.68 (5th).

The Tremec TKX has three available shifter mounting points, with the forward-most being within a 1/2-inch of the original McLeod’s position.

Fortunately, the TREMEC TKX fit nicely in the T-Rex project car’s transmission tunnel, despite being about 1.5-inches longer. The TKX comes with three shifter mounting options with the forward-most positioning the shift lever approximately a foot back from the bellhousing.

For what’s worth, McLeod is owned by the Wharton Automotive Group headed by noted Funny Car racer Paul Lee, and the firm has also acquired Silver Sport Transmissions, the nation’s largest TREMEC distributor— it made good sense to keep it “all in the family.”

Mark Williams Enterprises manufactured a chrome moly steel driveshaft (left) with beefy 1350-series U-joints. To attach it to the Camaro-based IRS center section, a billet aluminum yoke from Sonnax was employed. An AME Multi-Link IRS is used, which features a late Camaro center section. In OEM form a vibration damper is employed. T-Rex’s MW driveshaft is dynamically balanced to G30 specs, so none is needed.

Attaching the transmission to the engine was facilitated by employing a Quick Time bellhousing. It’s manufactured from a premium grade steel using a unique spin-forming process and rated at 80,000 psi tensile strength. It’s also SFI 6.1 certified, which is a requirement of most race sanctioning organizations.

Configuring the driveshaft had its own set of unusual parameters. Up front, the TKX transmission output shaft has 41 splines, same as a Ford C6 transmission.

With the original transmission the shifter was about 13-inches back of the bellhousing. The TREMEC’s front mount was within 1/2-inch, so no major tunnel mods were needed.

On the pinion side, things are more complicated. T-Rex is equipped with a multi-link IRS from Art Morrison Enterprises, which utilizes the center section from a late Camaro. But instead of a common yoke, the unit has a pad with three mounting holes designed to accommodate a vibration damper. Fortunately, Sonnax manufactures a sturdy billet aluminum yoke designed to employ U-joints.

To build the custom driveshaft we turned to Mark Williams Enterprises. The company offers them in aluminum (6061 and 7075 alloy), mlld steel, chrome moly or carbon fiber. While a lighter driveshaft contributes to improved performance, the actual shaft length in

T-Rex is only about 12-inches long, so the weight advantage of a 7075 T-6 aluminum shaft over 4130 chrome moly is only about three pounds. And that weight is directly amidships, so it’s not really a front/rear balance issue. As you might suspect, the steel shaft costs less. Bingo.

You might be interested to learn that M-W has developed a database that allows the company to precisely determine the weight of any material/length driveshaft for comparative purposes. They also have a critical speed data that pinpoints at what RPM a driveshaft will begin to “whiplash.” The length of the shaft, material stiffness, thickness and diameter are all factors. Given the shortness of T-Rex’s shaft, any of the materials could have been employed.

Like all driveshafts manufactured by Mark Williams, T-Rex’s unit has been dynamically balanced to G30 specifications. It’s also SFI 43.1 certified.

A custom shift handle was made from 1/4-inch aluminum (shaped to blend in with a 5/16-inch clevis), with the knob re-purposed from a bottle of “Shift” series wine from Adobe Road and attached via an aluminum spud.

One last item in the driveline installation was the shift lever. Ordinarily, you’d simply select a shaft that’s of optimum length and order it. That won’t work for T-Rex, because the seats are very low in relation to to the transmission’s position and commercially available shifters are too long.

Here’s an under-the-car shot of the new driveshaft assembly installed. The crossmember and tunnel structure combine to make a 360-degree driveshaft safety hoop.

In-car measurements dictated a 4-inch long lever needed to facilitate the driver’s forearm to be horizontal for optimum kinetic efficiency. The lever was fabricated out of 1/4-inch aluminum and the shift knob attached using an aluminum “spud” attached to a QA1 5/16-inch clevis. The shift knob came off a special Adobe Road Winery “Shift” 750 mL wine bottle. It’s a yummy Zinfandel blend in the company’s “Racing Series” if you’re interested. And the shift pattern matched that of the gearbox.

The shifter’s 4-inch length was determined by measuring the driver’s forearm position; horizontal to the ground is agronomically preferred. “CAD” technology (cardboard aided design) was used for the mock-up.

Next on the agenda is fabricating and fitting the diffuser, finishing off the enlarged rear wheelwells (making the “tub” some 1.5-inch larger than stock, and building a special wheelwell-accessible compartment to house the compact Odyssey battery. Then we’ll commence tackling the wiring.

About the author

Jim Campisano

Tech Stories

News

News

Build your own custom newsletter with the content you love from Street Muscle, directly to your inbox, absolutely FREE!

© 2025 Power Automedia. All rights reserved.

We will safeguard your e-mail and only send content you request.

We’ll send you the most interesting Street Muscle articles, news, car features, and videos every week.

We promise not to use your email address for anything but exclusive updates from the Power Automedia Network.

We will safeguard your e-mail and only send content you request.

Thank you for your subscription.

We think you might like…

We think you might like…

Thank you for your subscription.